|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

SACHS 48 mm FORK

|

|

|

|

This applies to the FIRST generation SACHS fork ONLY. NOT the 2014 to current model open chamber or the current race edition closed chamber.

For ALL models Sachs fork, we have a very good stock of the original OEM 7 mm I.D. shims to carry out your re-valve and set up. We DO NOT offer these shims for outright sales, they are ONLY available to our customers having their work done at our shop.

These are NOT modified 6 mm shims that are prone to failure, poor fit and finish. We are pretty surprised at what we have seen some shops do to overcome this hard to obtain shim size in practical dimensions for off road applications.

|

|

|

|

|

|

|

Here is some very basic specifications and information you should have. This won’t fix the fork, not even close. But it may help you service or consider it.

|

|

|

|

|

|

There is a new player in the Motocross and Enduro fork manufacturer’s market. Sachs has been around for a long time and this is their offering of a full size 48 mm non re-circulating cartridge fork. There is very little to no general information that we have found from the manufacturer of this fork, here are a few specs and tips you may find helpful. The specs were from a top shelf 2009 Gas Gas EC250 Race model.

|

|

|

- Weight 9.07 Kg, 20.0 lbs/pair. Up .7 Kg, 1.5 lbs from last year

- 48 mm stanchion tube

- Claimed travel, 295 mm 11.6”

- Upper clamp diameter 54 mm

- Lower clamp diameter 59.25 mm

- Spring is 43.3 O.D. x 460 mm long

- Damper rod O.D. 12/13 mm

- Piston dia... 30 mm, 24 mm triangle rebound face shims

- Cartridge tube O.D. 34.2 mm

- Base valve 30 mm 26 mm face

- Guide Bushing 48 I.D. x 15 x 2 mm

- Slide Bushing 48 O.D. x 20 x 1 mm

- Shim I.D. 7 mm, limited availability.

- Fluid level 80 mm to 140 mm 5 to 7.5 wt.

- 18 total clicks compression, 20 total clicks rebound

|

|

|

Download Engineering PDF drawing of base valve here

|

|

|

|

These PDF documents may not represent what may be installed in your specific fork, information only

|

|

|

|

Download Engineering PDF drawing of cartridge here

|

|

|

|

|

|

|

|

The components we had in our shop had been through several races and had a previous re-valve and set up elsewhere. This example was showing some wear and tear. This cap will differ by model, servicing this fork is similar to most others except for,

|

|

|

|

The Fork Cap

|

|

|

|

- Slot head rebound adjuster.

- 50 mm 10 point main cap.

- 19 mm hex socket (inner) for adjusting pre-load, up to 10 mm additional load.

- 2 mm socket head for air bleed.

- 4 pin, 3 mm O.D. on 34 mm diameter to access pre-load adjustment assembly.

NOTE: Do not remove the 4 pin retainer until you have the cap off of the damper rod! Very small parts can fall into the fork. Remove this to clean and service the pre-load adjuster assembly. You might want to read on further before you remove the cap from the damping rod. If your rebound adjusting screw has no detent clicks, chances are there is a 1.5 mm steel ball now within your fork. You’ve been warned!

|

|

|

|

|

|

|

|

|

|

|

Before removing the 10 point 50 mm main cap, open the rebound adjusting screw (counter clockwise) until it lightly stops, then proceed removing the main cap from the upper tube

|

|

|

|

. Now is a good time to NOTE, the rebound adjusting screw threads into the inner bore of the damping rod, ALSO the cap threads onto the O.D. of the damping rod. You will loosen both threads at the same time, Isn’t that SWELL! As you remove the cap from the damping rod, make certain the adjusting screw is coming out with the cap or once again, the tiny balls may fall! Be careful going back together with this afterthought of an adjuster, its a booby trap if your not paying attention.

|

|

|

|

|

|

|

Pull down the spring and slip your retaining plate in below the damper rod lock nut, a 19 mm open end will hold the lock nut as you loosen the 19 mm socket head. Make sure the rebound screw is coming out with the cap assembly.

|

|

|

|

|

|

|

The rest of the fork is similar (but very different design) to any other non re-circulating cartridge fork in its servicing procedure. If you are going into the cartridge cylinder to address the rebound and check/mid valve system you will need some special tools and careful procedures to remove the cylinder head. Best of luck here, we designed and machined our own removal tools to carry out this procedure. Now, to install this style cap

|

|

|

|

|

|

|

|

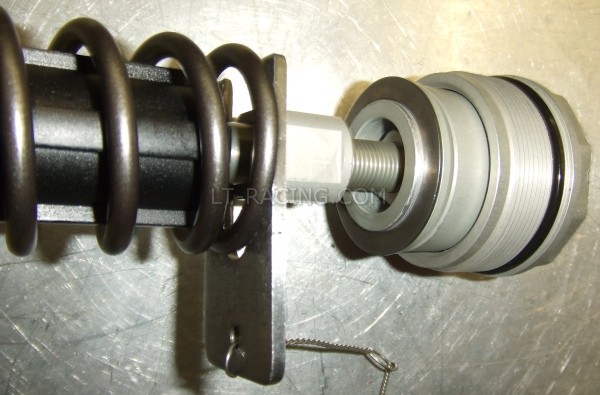

These are the components of the adjustable pre-load fork cap

|

|

|

|

|

|

|

|

With the cap serviced and reassembled, run the damper rod lock nut all the way down the threads, install your spring and spring holding plate, then carefully thread the cap onto the damping rod until it comes to a light stop, then back it out about one half turn.

|

|

|

|

|

|

|

|

Now carefully begin threading the rebound adjusting screw into the damper rod inside threads, as this engages the inner threads, let the cap continue to thread onto the outer damping rod threads as well. Make sure the adjusting screw is fully threaded into the damping rod until it comes to a soft stop and make sure the cap is fully engaged as far as possible onto the damping rod, then bring the lock nut up to the cap. Hold the cap with your 19 mm hex socket as below and snug them up. All the parts are aluminum, so be careful.

|

|

|

|

|

|

|

|

Like we said before, the rest of the fork is fairly similar to other cartridge forks as far as servicing and maintaining them. The 48 mm Sachs fork has some tuning issues engineered into it from the factory. We find it very hard to believe anybody spent any real world time actually evaluating its performance, even at the highest level of competition racing. These issues won’t magically heal up with break in time, that is just marketing from anyone who states this and is not acceptable. The Sachs fork and shock components supplied for off road, Enduro or MX machines are very well constructed with their own inherent quirks, but a bad execution in set up is just that. Contact us when you’ve had enough punishment, we can fix it for you no matter what type of riding you do or what level you ride at.

|

|

|

|

|

|

|

|

|

|

|

|

|

Telephone 360-871-2259 FAX 360-326-7282 E-mail les@lt-racing.com

|

|

|

|

6487 Knight Dr. SE Port Orchard, WA 98367

|

|

|

|

Copyright 2009 LT Racing inc.

|

|

|

|

Marzocchi, WP, Sachs, Ohlins, KYB, Showa. servicing, tuning, revalving, forks, shocks,Honda,Kawasaki,Suzuki,Yamaha, TE, TC, TXC, WR. CR, CRF, YZ, KX, KXF, RM, RM-Z, EC, DE, MC, RR, RS

|

|